micro labs walk in interview for production and packing – OSD Manufacturing facility

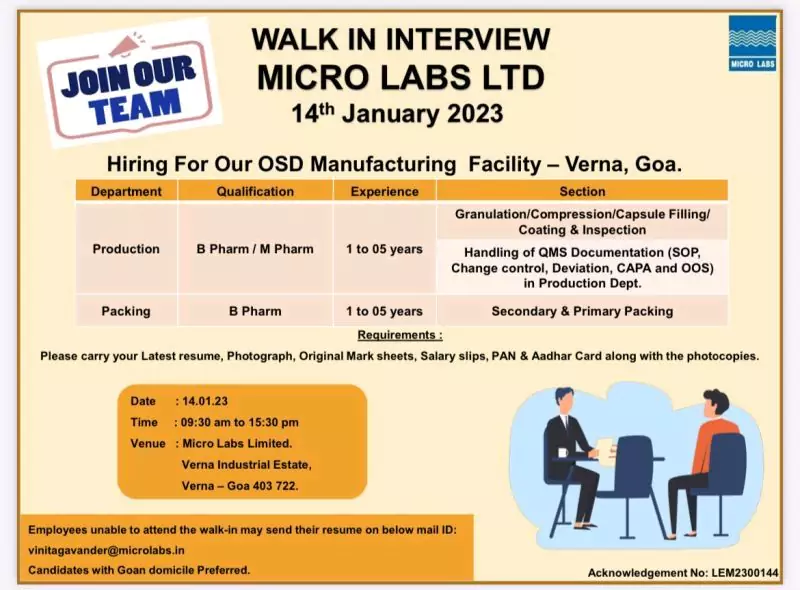

WALK-IN INTERVIEW at MICRO LABS LTD on 14th January 2023 for production, packing departments

Hiring For Our OSD Manufacturing Facility – Verna, Goa.

Micro Labs Limited is an Indian-based pharmaceutical company that manufactures and markets a wide range of pharmaceutical products. It was founded in 1984 and is headquartered in Bangalore. The company specializes in the manufacturing of a wide range of pharmaceutical products including Tablets, Capsules, Liquids, Ointments, Injections and Dry syrups. They have a wide range of products across various therapeutic areas like Cardiology, Neurology, Diabetology, Gastroenterology, Pediatrics, Gynecology and Nephrology.

👉 Never Miss a Pharma Job Again

💼 Join our LIVE WhatsApp Group & Get Instant Updates. 📢 Click below to join:

📱 Join Click HereThe company has several manufacturing facilities that are WHO-GMP and ISO 9001:2015 certified. They also have a strong presence in the domestic market as well as a significant international presence, exporting their products to over 60 countries. Micro Labs is also known for their R&D capabilities in the field of generics, biosimilars and new chemical entities (NCEs)

Micro Labs Limited is also known for its strong commitment to corporate social responsibility and is involved in various social welfare activities. The company has received several awards and recognitions for its quality of products and services, and its commitment to corporate social responsibility.

Production – micro labs jobs

Qualification: B Pharm/ M Pharm

Experience: 1 to 05 years

Section: Granulation/Compression/Capsule Filling/ Coating & Inspection

Handling of QMS Documentation (SOP, Change control, Deviation, CAPA, and OOS) in the Production Dept.

Packing – micro labs jobs

Education: B Pharm

Experience: 1 to 05 years

Requirements: Secondary & Primary Packing

Please carry your Latest resume, Photograph, Original Mark sheets, Salary slips, PAN & Aadhar Card along with the photocopies.

Date: 14.01.23

Time: 09:30 am to 15:30 pm

Venue: Micro Labs Limited., Verna Industrial Estate, Verna – Goa 403 722.

Employees unable to attend the walk-in may send their resume on below mail ID: vinitagavander@microlabs.in

OSD (Oral Solid Dosage) manufacturing facility refers to a facility that is used to manufacture oral solid dosage forms of pharmaceutical products, such as tablets, capsules, and powders. These facilities typically include several different types of equipment, such as tablet presses, capsule fillers, mixers, granulators, and packaging equipment.

The process of OSD manufacturing typically involves several steps, including:

- Formulation development: This includes the development of the recipe or formula for the product, which includes the active ingredient(s) and excipients.

- Mixing and granulation: This step involves mixing the active ingredients and excipients together, and then granulating the mixture to create a uniform powder.

- Compression and encapsulation: This step involves using a tablet press or capsule filler to compress the powder into tablets or fill it into capsules.

- Coating: This step involves applying a coating to the tablets or capsules to improve their appearance, taste, or stability.

- Inspection and packaging: This step involves inspecting the tablets or capsules for defects, and then packaging them in containers or blister packs for distribution.

An OSD manufacturing facility must comply with the Good Manufacturing Practices (GMP) regulations and guidelines set by regulatory authorities such as US FDA, EU GMP, WHO GMP etc. These regulations ensure that the products are manufactured, controlled and monitored in a consistent and controlled manner, and they are safe, effective, and of good quality. The facility must also have a Quality Control department that monitors and analyzes the product quality and the process parameters to ensure compliance with the GMP regulations and guidelines.